Magnetic Robotic Crawler for Tank Cleaning

January 28, 2025What is Robot as a Service (RaaS)?

February 20, 2025Industrial tanks in the oil and gas, chemical, and wastewater industries accumulate sludge, residues, and hazardous deposits over time. Traditional cleaning methods require human entry into confined spaces, exposing workers to toxic gases, high temperatures, and potential accidents. This is where robotic tank cleaning emerges as a game-changer.

Robotic tank cleaning enhances safety, increases efficiency, reduces downtime, and ensures a thorough cleaning process. In this step-by-step guide, we will explore how robotic tank cleaning works and why industries are rapidly adopting this innovative technology.

Understanding Robotic Tank Cleaning

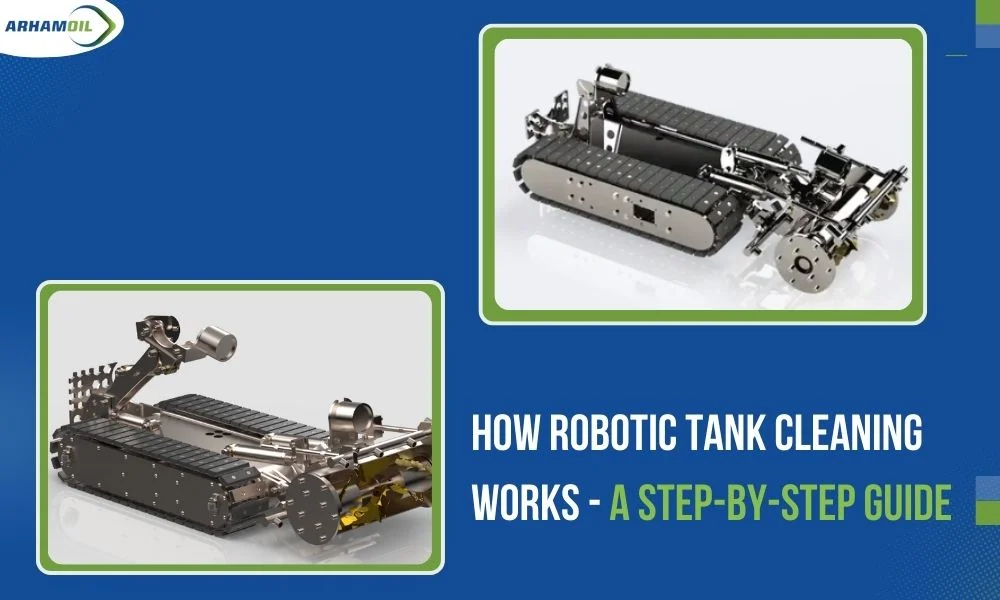

Robotic tank cleaning involves the use of advanced automated machines that enter and clean storage tanks without human intervention. These robots are equipped with high-pressure cleaning systems, advanced sensors, and remote-control operation to ensure optimal performance.

The process of robotic tank cleaning follows a structured approach to achieve maximum efficiency and safety.

Step 1: Initial Inspection and Assessment

Before deploying robotic systems, a comprehensive assessment of the tank is conducted. This includes:

- Identifying the type and level of sludge accumulation

- Assessing the tank’s structural integrity

- Checking for hazardous gases and explosive atmospheres

High-resolution cameras and sensors are used to capture real-time data, enabling operators to develop a customized cleaning plan.

Step 2: Preparing the Tank for Cleaning

The tank is prepared to ensure a smooth robotic operation. This may involve:

- Draining excess liquid to reduce sludge volume

- Neutralizing hazardous gases using ventilation systems

- Implementing safety protocols to prevent leaks or spills

These measures create a controlled environment, allowing the robotic system to function effectively without any disruptions.

Step 3: Deploying the Robotic Cleaning System

Once the preparation is complete, the robotic cleaning system is deployed into the tank. These robots are designed with:

- Magnetic Crawlers: For better grip on tank surfaces

- High-Pressure Nozzles: To break down stubborn sludge deposits

- Automated Brushes: To scrub walls and remove residual buildup

- Vacuum Suction Units: To extract sludge and waste material

Operators control the robot remotely, ensuring precision cleaning while monitoring progress through real-time video feeds.

Step 4: Sludge Removal and Collection

One of the biggest advantages of robotic tank cleaning is the efficient removal of sludge. The robotic system systematically:

- Uses high-pressure water jets to break down hardened sludge

- Directs the sludge towards vacuum suction units

- Pumps out the waste material for further treatment or disposal

This automated process ensures minimal sludge residue is left inside the tank, preventing contamination and improving storage capacity.

Step 5: Final Cleaning and Inspection

Once the sludge is removed, a final cleaning phase is carried out using:

- Eco-friendly cleaning agents to eliminate residual contamination

- Rinse cycles to remove any remaining deposits

- Drying mechanisms to ensure the tank is ready for use

After cleaning, a thorough inspection is performed using cameras and sensors to confirm the tank is free from contaminants and fully operational.

Step 6: Waste Treatment and Disposal

The extracted sludge is processed to recover valuable hydrocarbons or disposed of using environmentally friendly methods. This includes:

- Oil Sludge Recovery: Extracting usable hydrocarbons for refining and reuse

- Bioremediation: Using microorganisms to break down harmful components

- Safe Disposal: Transporting non-recoverable waste to authorized facilities

This sustainable approach minimizes environmental impact and maximizes resource utilization.

Advantages of Robotic Tank Cleaning

Robotic tank cleaning offers multiple advantages over traditional methods:

- Enhanced Safety: Eliminates human entry, reducing risks associated with toxic exposure and confined space operations.

- Increased Efficiency: Robots work continuously without fatigue, reducing cleaning time significantly.

- Cost Savings: Less downtime, reduced labor costs, and optimized sludge recovery make robotic cleaning a cost-effective solution.

- Environmental Sustainability: Minimizes water usage, prevents chemical contamination and supports eco-friendly waste disposal practices.

- Precision Cleaning: Real-time monitoring and automated control ensure thorough cleaning, improving tank performance and longevity.

Why Choose Arham Oil for Robotic Tank Cleaning?

At Arham Oil, we specialize in providing the best robotic tank cleaning services designed for maximum safety and efficiency. Our robotic systems are equipped with the latest technology to handle even the most challenging cleaning tasks.

- Expertise & Experience: Years of industry experience in tank cleaning solutions.

- Advanced Technology: High-performance robotic systems for precise and thorough cleaning.

- Eco-Friendly Approach: Sustainable cleaning practices that minimize environmental impact.

- Client-Centric Services: Tailored solutions to meet industry-specific requirements.

Arham Oil is committed to revolutionizing tank maintenance with innovative robotic cleaning solutions. Contact us today to learn more about how we can help you maintain cleaner, safer, and more efficient storage tanks.