Rise of Robotic Tank Cleaning in India

India's industrial sector, spanning across diverse domains such as petrochemicals, pharmaceuticals, food processing, and manufacturing, relies heavily on storage tanks for the containment of various liquids and chemicals. With stringent regulations, safety concerns, and operational efficiency becoming paramount, the adoption of advanced cleaning technologies like robotic tank cleaning has emerged as a game-changer in the Indian industrial landscape

Evolution of Robot Tank Cleaning

Traditionally, tank cleaning in India has been a labor-intensive and hazardous task, often involving manual laborers entering confined spaces to perform cleaning operations. However, this approach poses significant risks to worker safety, leads to prolonged downtime, and may result in environmental contamination. Recognizing these challenges, industries are increasingly turning towards robotic solutions to revolutionize their tank cleaning processes.

Future of Tank Cleaning in India

The Indian industrial landscape, characterized by diverse sectors like petrochemicals, pharmaceuticals, and manufacturing areas largely dependent on storage tanks. Traditional tank cleaning methods often involve manual labour, posing significant risks to workers and leading to operational inefficiencies. Arham Oil has emerged as a pioneer in revolutionizing this process with its advanced hydrocarbon waste cleaning robots.

Challenges and Opportunities in Robotic Tank Cleaning

Despite the numerous benefits, the adoption of robotic tank cleaning technology in India faces certain challenges, including initial capital investment, technical expertise, and industry-wide awareness. However, as industries recognize the potential long-term benefits and regulatory pressures continue to increase, the market for robotic tank cleaning solutions is poised for significant Growth.

Robotic tank cleaning is reshaping the landscape of industrial maintenance in India, offering a safer, more efficient, and environmentally sustainable alternative to traditional cleaning methods. With advancements in technology and increasing demand for operational excellence, the adoption of robotic solutions is expected to accelerate, driving innovation and productivity across various industrial sectors in the country. As India's industrial landscape continues to evolve, robotic tank cleaning stands at the forefront of transformative change, ensuring safer, cleaner, and more efficient operations for years to come.

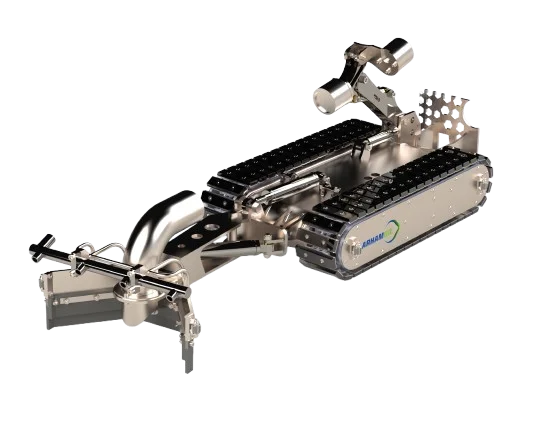

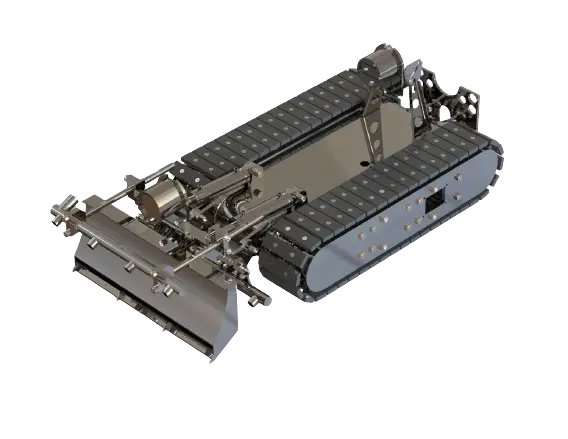

ROBOT named MUSHAQ 2.0

Dimensions

- LxBxH: 30 x 20 x 8 inches.

- Hydraulic Power Pack: 15 HP

- Jetting Pressure: 1 to 50 bar

- Suction Volume: 5 to 20 cu.m per hour

- Maximum Range: 100 m.

- Storage tank Cleaning

Application

- Pipeline Cleaning Application

- Cooling Tower sump cleaning

- ETP/OWS pit Cleaning.

Features & Purposes

- Upper Nozzles - Hitting the Sludge mounts.

- Lower Nozzles – Washing the Tank Bottom surface.

- Hydraulic Driven

- 3-4 Types of Augers

Hazards

- Green House Emissions.

- Drowning Effect

- 3. Foul Smell

- Hydraulic Driven Robot with Hydraulic Arm attached Submersible Pump

- 25 mm Solids can be pumped off easily. Mechanical Agitation to mobilise the Sludge in lagoons

- Ease of Movement inside the lagoon. Contains: Nozzles system, Pumping system - Hydraulic Driven

Arham Oil's Robotic Tank Cleaning Solutions

- ATEX-Certified Robots: Our robots are designed to operate in hazardous environments, including those with flammable gases and vapors.

- Real-Time Monitoring: Our robots are equipped with cameras and sensors that allow for real-time monitoring of the cleaning process, ensuring optimal efficiency and safety.

- Customized Solutions: We offer customized solutions tailored to your specific tank requirements, ensuring maximum effectiveness.

Why Choose Robotic Tank Cleaning?

- Enhanced Safety: Robotic tank cleaning eliminates the need for human workers to enter confined spaces, mitigating the risk of accidents, injuries, and exposure to hazardous substances. Operators can control the cleaning process remotely, ensuring personnel safety while maintaining operational efficiency.

- Efficiency and Precision : Industrial tank cleaning robot system are equipped with advanced sensors and algorithms, allowing for precise cleaning of tanks with minimal downtime. These systems can navigate complex tank geometries, removing contaminants thoroughly and efficiently.

- Cost-Effectiveness : While the initial investment in robotic tank cleaning technology may be substantial, the long-term cost savings are significant. Reduced labor costs, decreased downtime, and enhanced operational efficiency contribute to overall cost-effectiveness in the maintenance of industrial tanks.

- Environmental Compliance : Robotic tank cleaning systems are designed to minimize waste generation and adhere to environmental regulations. By reducing the use of water, chemicals, and energy, these systems contribute to sustainable industrial practices.

- Versatility and Adaptability : Robotic tank cleaning systems can be customized to suit the specific requirements of different industries, accommodating various tank sizes, shapes, and types of contaminants. This versatility makes them suitable for a wide range of applications across diverse industrial sectors.

- Expertise: Our team of experts has extensive experience in robotic tank cleaning, ensuring that our solutions are reliable and effective.

- Innovation: We are committed to staying at the forefront of technology, continuously developing new and innovative robotic solutions.

- Customer Satisfaction: We prioritize customer satisfaction and provide exceptional service throughout the entire process.

Experience the Future of Tank Cleaning

By choosing Arham Oil's robotic tank cleaning solutions, you can ensure the safety of your workforce, improve operational efficiency, and minimize environmental impact. Contact us today to learn more about how our robots can transform your tank cleaning operations.

Tank Cleaning Robots Customized Solutions

At Arham Oil, we understand that each tank cleaning project is unique. That's why we offer customized robotic tank cleaning solutions tailored to the specific requirements of your facility. Our advanced technology can adapt to different tank sizes, shapes, and cleaning needs, ensuring optimal results every time. By choosing our services, customers benefit from a tailored approach that minimizes downtime and maximizes efficiency. Our commitment to safety and precision ensures that every job is completed to the highest standards, making us the ideal partner for your tank cleaning needs.